Industrial safety

Area, strategic goals and metrics

- fostering a safety culture and adhering to the highest occupational health and safety standards

- reducing workplace injuries by 10 % annually

- zero fatalities, and reducing the number of incidents by 10 % annually

Key projects and highlights of 2022

Total injuries- reducing risks of traffic accidents

Key projects and highlights of 2022

- paying special attention to disease prevention and health improvement among the employees of all production sites;

- providing employees with access to high-quality affordable healthcare

Key projects and highlights of 2022

- improving safety competencies

- keeping employees motivated to stay safe and protect others

Key projects and highlights of 2022

All employees of PhosAgro Group and its contractors need to go back from work to their loved ones in perfect health. This is the underlying principle of all our efforts to ensure safe, healthy and comfortable workplace conditions.

Our Strategy to 2025 focuses on fostering a safety culture and adhering to the highest occupational health and safety standards. In 2022, we continued to implement our Health and Safety Strategy, which defines key focus areas and target initiatives to reduce the risks associated with various operations.

PhosAgro Group is consistently improving its safety culture, employee responsibility and awareness, hazard identification procedures and danger prevention measures by putting managers at all levels in charge and studying and applying best health and safety practices. We apply continuous efforts to identify and reduce health and safety threats to PhosAgro Group employees, contractors and visitors to the Company’s sites.

The Company’s relevant goals and objectives, both strategic and day-to-day, are based on huge volumes of data derived from internal and external audits, inspections, incident investigations, employee recommendations and feedback.

We pay special attention to making our health and safety system compliant with applicable laws and the highest international standards.

To this end, we have introduced a multi-tier health and safety management system involving managers of all levels. In 2008, the Company introduced an integrated health and safety management system in line with BS OHSAS 18001. In 2021, Apatit’s Cherepovets site was certified and in 2022 successfully audited for compliance with ISO 45001:2018.

Occupational health functions play a key role in ensuring safety at our facilities.

Their main objectives are:

- taking steps to ensure workers’ compliance with health and safety requirements;

- monitoring workers’ compliance with OHS laws and regulations, the Collective Bargaining Agreement, OHS agreement and other internal regulations;

- preventing workplace injuries, occupational diseases and work-related illnesses and improving workplace conditions;

- advising workers on, and raising their awareness about, occupational health and safety;

- studying and disseminating best OHS practices and promoting occupational health.

Apart from applicable laws, these activities are regulated by:

- health and safety SOPs at the facility (shop) level;

- production SOPs;

- worker health and safety instructions;

- corporate standards;

- process regulations;

- accident management action plans, etc.

For better OHS communication with employees, we have adopted the Regulations on the OHS Communication System. Pursuant to the Regulations, the OHS communication system is divided into internal and external communications, and provides for a feedback procedure:

- regular OHS meetings at business units and enterprises;

- OHS meetings at production sites, departments and facilities;

- union and union committee meetings (for feedback from OHS officers);

- corporate e-mail;

- corporate periodicals;

- local health and safety committees;

- employee loyalty surveys;

- OHS questionnaires.

Internal OHS communication is achieved through:

- local health and safety committees;

- management meetings and conferences to discuss the health and safety performance of our enterprises; regular OHS meetings in departments, on production sites and at facilities;

- health and safety bulletin boards, posters and other visuals;

- corporate television (screens), intranet site, e-mail;

- corporate periodicals;

- education by OHS officers (including one-on-one meetings, training, mentoring, supervision, etc.).

Local health and safety committees

Since 2014, health and safety committees have been functioning at the Group’s companies. They are both an integral part of our OHS management system and a form of employee participation in it. In their work, these committees rely on the principles of social partnership. As part of their activities, health and safety committees draft and improve programmes to join efforts of the employer, employees and trade unions in ensuring health and safety.

In 2022, we revised our regulations on health and safety committees, with meetings to be held on a monthly basis according to the new version. At meetings, information exchange and reporting are multilateral, as both health and safety functions and local unit heads report on health and safety progress. The latter can also address their questions and proposals directly to the management and the health and safety function. All resolutions are documented in minutes of the meetings. In 2022, health and safety committees held 35 meetings and adopted 560 resolutions.

Workers are represented at committee meetings by heads or representatives of local unions.

As part of these workstreams health and safety committees consider the following topics:

- “Golden Rules” of OHS;

- Safety Culture Transformation Project;

- OHS leadership;

- OHS motivation;

- effective OHS communications;

- contractors' safety;

- PPE effectiveness;

- trade union report.

Meeting agendas comprise nine workstreams

Improving contractor safety practices

Measures to ensure safety of contractors’ employees temporarily working at our production and other facilities are an integral component of our OHS strategy. They include the selection of contractors based on a health and safety qualification assessment, briefings, and training to contractor employees, along with relevant compliance audits.

ESG assessment is a major factor in contractor selection.

Internal and external industrial safety audits

In line with statutory requirements, PhosAgro Group is subject to scheduled external audits by Russian authorities, including the Federal Service for the Supervision of Environment, Technology and Nuclear Management (Rostekhnadzor), State Labour Inspectorate, Federal Service for Surveillance on Consumer Rights Protection and Human Wellbeing (Rospotrebnadzor), the Ministry for Civil Defence, Emergencies and Elimination of Consequences of Natural Disasters (EMERCOM), etc. We may also engage consulting companies, or international associations of which the Group is a member to conduct additional external audits of compliance with international standards, or as part of a special assessment of workplace conditions.

In 2022, state supervisory authorities carried out 189 audits at Apatit and its managed companies. The higher number of audits (up from 132 in 2021) was due to due to an increase in the number of audits conducted as part of the continuous state supervision of hazardous production facilities of hazard class 1, with Apatit having 17 such facilities.

We also run internal audits conducted by our OHS departments and directorate, managers and employees exercising production H&S control.

After external and internal audits, the Company issues orders and instructions outlining remedial action plans and establishing the deadlines and responsible persons. Identified breaches are remedied within the agreed time limits, and gaps that can be eliminated at no additional cost are addressed immediately.

The Company has a procedure for drafting, submitting and reviewing reports on internal and external OHS audits. The results of all internal and external assessments and audits are recorded in the Safety and Instructions (Shift Assignments) management systems for further analysis, gap identification and elimination monitoring. We also submit all relevant reports to state supervisory bodies and statistical agencies in accordance with the Russian laws.

The following strategic risks affect our OHS objectives:

The Group develops corrective measures as necessary and unlocks opportunities to mitigate those risks. Below you can find more information about what we do on this front.

OHS-specific risks are:

We are constantly working to assess and mitigate risks. We perform risk assessment and identify material risks using our dedicated proprietary methodology. Following hazard identification and risk assessment, the unit’s OHS officer compiles a List of Occupational Risks, which is then used as a basis for the Company’s List of Material Occupational Risks.

In accordance with an established procedure, information about incidents is provided by eyewitnesses to the supervisors in charge and by those supervisors to the dispatcher of the enterprise. Next, the dispatcher notifies the designated persons using text messages and phone calls.

Industrial accidents and incidents are investigated in accordance with legislative requirements and internal procedures to determine the root causes. The Company encourages its staff to disclose information on potential sources of danger to worker health and life.

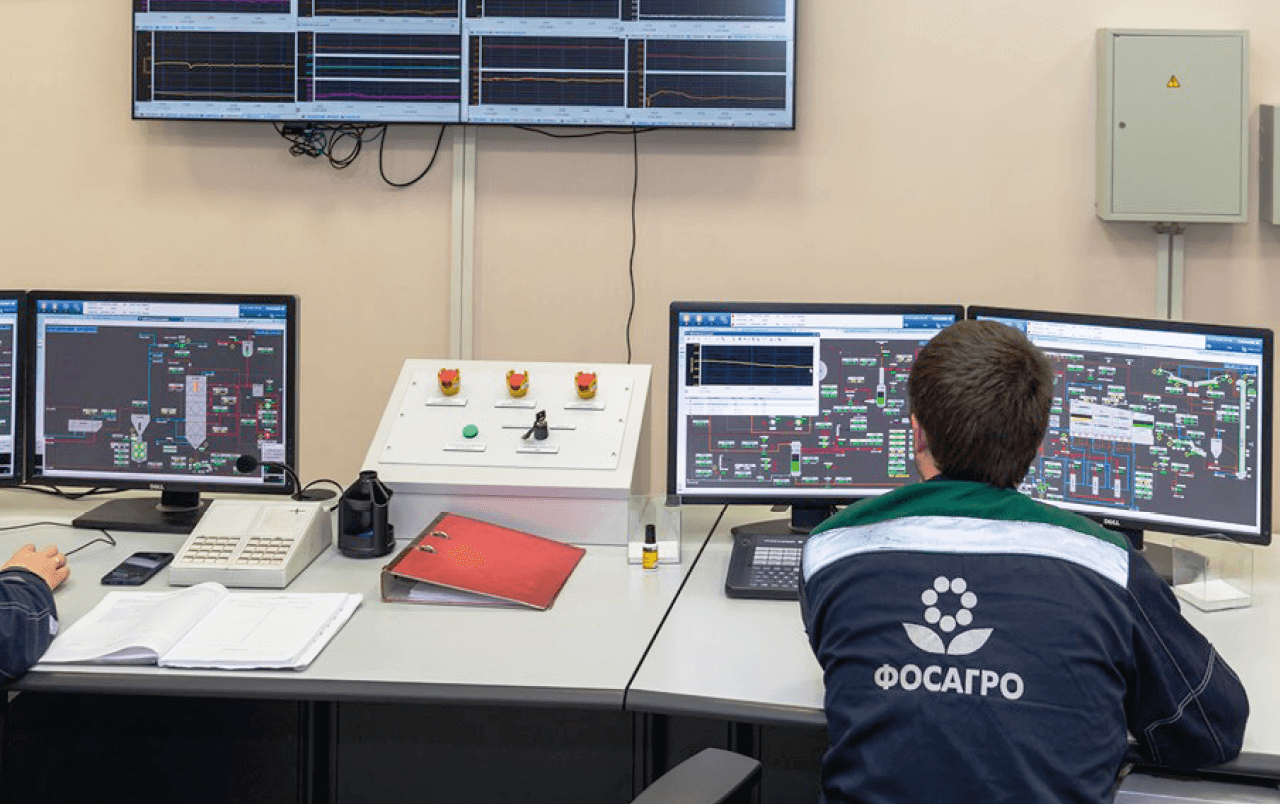

For better OHS efficiency, and to automate and streamline the relevant processes, we have introduced and now use the Safety and Instructions (Shift Assignments) management systems. Both systems include a Risk Management module. The module enables internal check list-based OHS assessment at all units of Apatit. The module’s new underlying principles help enhance production H&S control, while its new functions facilitate operation, monitoring and analysis.

The Company has a formal procedure for addressing workplace hazards. When a hazard is identified, employees are required to suspend work and report it to their supervisors directly or via the Public Scrutiny mobile app (on an anonymous basis if necessary). The supervisor uses the report to assess the risk and develop a remedial action plan.

Risk assessment takes into account the following aspects:

Roll-out of the OHS remote monitoring system at the Cherepovets site of Apatit

Starting from 2021, Apatit’s Cherepovets site (fluosilicate acid storage facility of the aluminium fluoride shop) participates in Rostechnadzor’s experiment to roll out an OHS remote monitoring system under Russian Government Decree No. 2415 On Experimental Roll-out of the Industrial Safety Remote Monitoring System dated 31 December 2020.

The experiment provides for the development of stand-alone remote monitoring technology for hazardous production facilities, and a relevant legal framework. As assumed, the technology will improve the overall reliability and monitoring efficiency of safety systems, and help reduce the associated paperwork and bureaucracy.

The pilot operation of the OHS remote monitoring system began in November 2022, with the process of data transmission to the Automated Information System of Rostekhnadzor currently being configured.

Emergency response procedures

At our sites, we have introduced the following emergency response and prevention measures compliant with the Russian laws:

The significant increase in OHS expenses is attributable to the rise in prices for personal protective equipment on the Russian market, as well as the expansion of OHS training programmes for employees and changes in the approach to organising such training as a result of the growing number of training programmes due to the adoption of Russian Government Resolution No. 2464 On the Procedure for OHS Training and Checking the Knowledge of OHS Requirements dated 24 December 2021.

Transport safety

The initiatives implemented by the OHS Department and transport departments to mitigate traffic accident risks includes drafting internal regulations to ensure safe operation of motor vehicles, self-propelled machines and rail transport, performing targeted and full-scope inspections of vehicles used by our contractors, subsidiaries, enhancing the competencies and skills of PhosAgro employees responsible for operating all types of transport, and introducing various technical solutions to mitigate risks of traffic accidents. Examples of such solutions in 2022 include optical projections of pedestrian crossings implemented at the Volkhov branch and visualisation systems for dangerous zones installed on self-propelled machines at the Kirovsk branch.

Work-related injuries

In 2022, the Company continued to perfect its health and safety management system and made significant progress in improving workplace safety. The total number of work-related injuries, both minor and major, significantly reduced across the Company's facilities in 2022, with 20 injuries reported compared to 41 in 2021. Of these injuries, five occurred to contractor employees, eight to PhosAgro’s own staff and seven to employees of subsidiaries and affiliates (compared to 16, 17 and 8 in 2021, respectively). We were deeply saddened by the fatality involving our employee which occurred at the production site of Apatit’s Kirovsk branch in December 2022. The investigation has been completed. We have thoroughly analysed the circumstances of the fatality and communicated conclusions and recommendations on preventive measures, including a range of technical and organisational steps, to the management and employees of the facility. This tragedy clearly shows the importance of further improving safety practices.

Most of the injuries reported in 2022 were related to chemical burns incurred while handling hazardous substances, as well as fractures resulting from falls and contact with moving and rotating objects and equipment. The main causes of work-related injuries in 2022 were poor work organisation, violations of labour and industrial discipline, and personal negligence of the injured parties.

The Company plans to continue implementing its safety improvement strategy by leveraging new safety tools and modern comprehensive solutions and approaches that have already proven effective, including:

- senior management’s leadership and commitment to health and safety;

- allocating sufficient funding to ensure occupational, industrial and fire safety;

- knowing and applying international and domestic best practices;

- improving the internal incident investigation process to identify and eliminate root causes;

- implementing project solutions and targeted programmes to improve workplace safety;

- providing employees with modern and effective personal and collective protective equipment;

- involving blue-collar workers (OHS officers) in directly managing health and safety in their business units;

- reviewing the structure and functions of occupational health, industrial safety and fire safety services with a focus on enhancing control and preventive work;

- selecting and appointing highly qualified leaders to key positions in occupational health, industrial safety and fire safety services;

- developing and implementing a system of incentives motivating all categories of employees for safe working practices;

- developing and updating e-courses to educate employees in corporate health and safety requirements;

- integrating corporate health and safety requirements into the work of contractors;

- digitalising data management processes to support high-quality analysis and effective management decision-making.

Worker training on occupational health and safety

In 2022, 10,800 employees of the CompanyApatit, including its branches and standalone business units. (around 80% of the total headcount) passed health and safety training and knowledge checks, including an ad-hoc one (vs 7,800 employees in 2021).

PhosAgro keeps working to improve OHS competencies and knowledge of its staff. Employees of the Company undergo online and in-person training arranged at our PhosAgro Education Centre.

Our e-courses are easy to understand since they are made in the form of illustrated slides with key highlights on them. In particular, we offer an e-course on corporate OHS standards. It is followed by tests to check the knowledge and understanding of the standards and requirements.

In 2022, we developed and rolled out four e-courses on the key occupational health and safety regulations:

- procedure for occupational safety audits using check lists;

- course in the Safety and Instructions (Shift Assignments) management systems for beginners;

- procedure for operations in a confined space;

- implementation of the railway transport safety management system at Apatit and its branches.

Whenever required, the courses developed earlier are updated following changes in the law and the Company’s internal regulations. In 2022, we updated the following e-courses:

- Occupational Health and Safety Golden Rules;

- working at heights;

- contractor safety requirements;

- investigation and communication of occupational health and safety accidents/incidents;

- management of contractors’ organisational and technical documents.

In 2022, 7,200 employees of the CompanyApatit, including its branches and standalone business units. (54% of the total headcount) completed 13 e-courses in occupational safety.

Apart from that, PhosAgro Education Centre organises OHS training, including that in basic fire safety and electrical safety, industrial safety pre-certification sessions, and drills in the Vysota training centre.

All our employees, from managers to blue-collar staff, receive occupational health and safety briefing and training as required by the Russian laws. Furthermore, the employees of the Company and some contractors are offered a number of additional courses.

To improve OHS training and remind employees about workplace safety, PhosAgro Education Centre creates animated videos.

In 2022, our health and safety management system covered 100% of the Company’s employees. All our employees (executives together with blue- and white-collar staff) take OHS training as required by the national laws, as well as additional training. The minimum required training is provided to each and everyone, including all visitors and contractors as part of the introductory briefing.

Raising awareness about OHS

To keep our employees well-informed about our safety measures, PhosAgro constantly develops and updates OHS check lists, presentations and other visual materials that emphasise the crucial information employees must rely on in various situations, including working on particular assignments, in order to stay safe.

Raising awareness about occupational health and safety, each month the Company issues check lists on the month’s topic.

In 2022, check lists were developed for the following topics:

- Rules for Working in Winter / Safe Driving and Walking in Winter;

- Safe Use of Stairs / Flights of Stairs;

- Golden Rules;

- Correct Use of PPE;

- OHS Motivation;

- Learn the Occupational Safety Rules;

- Disease Prevention;

- Control of Briefings for Each Shift;

- Safe Earthworks;

- Occupational Safety at Low Temperatures, etc.

In 2021, pilot business units of Apatit launched briefings for each shift. This initiative was rolled out at all business units in 2022.

The key objectives of such briefings are:

- revising industrial dangers/hazards, OHS requirements (as set out in the Company’s internal regulations, OHS guidelines, technical and operational documents), and safe work practices;

- fostering leadership skills among mid-level managers;

- developing managers’ communication skills.

In 2022, in order to draw attention of the Company's employees to incidents, an illustrated Incident Almanac was developed. This is a printed handbook describing all incidents in 2021 shown as animations. This format clearly illustrates the circumstances of incidents, draws attention to their causes and actions to prevent similar incidents in future.

Changes to labour safety promotion programmes

Senior executives (CEOs of the Company and its business units, as well as their direct subordinates) recognise the importance of OHS and are committed to safety and ready to take necessary managerial decisions. Since 2014, PhosAgro has had a system of KPIs that uses uniform standards linking the size of management remuneration to the efficiency of OHS measures, among other things. In particular, the Company established the following KPIs with regard to OHS:

- LTIFR covering all staff categories, including contractors;

- zero fatalities among all employee categories, including contractors;

- timely implementation of action items from improvement notices issued by supervisory authorities;

- industrial safety indicator;

- zero industrial accidents.

The Company has developed OHS promotion programmes to maintain each PhosAgro employee’s interest in ensuring their own safety and the safety of those around them, as well as to encourage the employees to take initiative and implement OHS improvements.

In 2022, we revised the employee labour safety promotion regulations, including the addition of a new incentive programme, Best Public Scrutiny User, which provides for quarterly cash bonuses to employees who show initiative.

Employee labour safety promotion regulations

A new programme since 2022 aimed at:

- engaging employees in the Public Scrutiny system (InSight mobile app);

- showing leadership and commitment to occupational safety among employees of Apatit and its branches by “submitting improvement ideas” or “reporting hazardous situations”.

Apart from that, the existing promotion programme includes:

In 2020–2022, there were no fatalities caused by occupational diseases.

Promotion of worker health

PhosAgro places a strong emphasis on disease prevention, health improvement, and high-quality affordable healthcare and prevention for the employees of all its production sites.

The Company takes part in the Health 360 programme run by the Russian Chemists Union to promote annual health self-assessments based on a dedicated questionnaire.

In addition, PhosAgro is a frequent participant in contests aimed at promoting and shaping best practices for safe operations and healthy lifestyles. One of such contests is the Russian Organisation of High Social Efficiency. The participation of PhosAgro’s facilities starts at the regional stage with submissions made in the category For Promoting a Healthy Lifestyle at Industrial Organisations.

In 2022, the Company continued introducing employee support programmes (mental health support, online advice for personal circumstances, etc.) and programmes to promote health and well-being (telemedicine, healthy diets, emotional unwinding, etc.).

All employees who have signed an employment contract with the Company benefit from long-term voluntary health insurance (VHI) covering a broad range of risks.

The benefits include:

Health insurance contracts are signed annually as part of long-term cooperation with the SOGAZ insurance company.

On-site clinics can provide accident and emergency care and specialist advice from a therapist, endocrinologist, neurologist, ophthalmologist, dentist and other doctors. PhosAgro also has mobile medical teams and organises screening sessions for its employees. The Company's facilities take part in federal level prevention campaigns, such as a high-profile all-Russian campaign called Cancer Watch: as part of it, 16 doctors of the National Medical Research Radiological Centre examined over 300 employees of PhosAgro’s Cherepovets facility.

PhosAgro’s production sites organise initial and regular check-ups and examinations of staff involved in potentially hazardous and/or dangerous activities.

Since 2010, the Company has been running a programme to improve social and working conditions by conducting annual scheduled repairs in all buildings housing social and sanitary facilities, canteens, and workplaces. In 2010–2022, PhosAgro invested over RUB 2.2 bln in the programme.

In 2022, the Company made further progress on its Occupational Health and Preventive Healthcare Programme by focusing on making workplaces more comfortable and putting in place break rooms. As regards workplace comfort, standard terms of reference were developed for the purchase of chairs for structural units, and a list of best models was compiled following their tests at structural units and polls at Apatit and its branches.

Psychological Relief Room, another project aimed at reducing employee’s emotional stress, kicked off in 2021 at the Balakovo branch. Going forward, the project will be extended to other facilities.

Starting from 2022, employees of all PhosAgro facilities have access to Telemed, a telemedicine service offered by SOGAZ. Furthermore, Apatit's Balakovo branch continues piloting the Doctor Nearby project run by DOCTIS, and collaboration is ongoing between Apatit and its branches with the DobroService platform offering online counselling on critical issues.

In 2022, the Company introduced changes to its menu of dietary and health meals provided to employees working in harmful conditions. Quality of the meals is subject to regular control in cooperation with the trade union.

Every day, canteens at the Company's facilities serve up to 600 people. The Company has a nutritionist on site to provide information and advice to employees, and all meals are assessed each quarter based on employee surveys, review of complaints, and canteen attendance levels. Employees can comment on the quality of meals in a real-time mode by completing a survey available in corporate canteens via a QR code. On top of that, we have a dedicated working group that attends all of Apatit’s sites to assess food quality and canteen conditions. As part of healthcare initiatives, staff canteens provide nutrition according to Diet No. 10 targeting patients with cardiovascular diseases.

In 2021, PhosAgro started a pilot project to use a traffic light labelling system for foods as a way to promote healthy dieting among employees. Also since 2021, we have been providing and broadcasting cooking workshops.

As part of preventive care and health promotion efforts for PhosAgro's employees and veterans in 2022, the Company purchased 2,670 vouchers for them to go to health resort facilities. In 2022, employees and their families received 947 free vouchers under the Wellness programme, with partial coverage of travel expenses to and from the recreation facility. Employees of the Company and their family members as well as veterans have year-round access to corporate health resorts at a reduced price.

PhosAgro’s facilities have corporate fitness centres, which include game halls, gyms and swimming pools and are available to employees on a daily basis. Pools offer classes in water aerobics and swimming lessons, both very popular among employees. At the Cherepovets facility, the fitness centre is attended by an average of 3,000 people per month; on days of mass classes, attendance has reached up to 250 visits per day since 2019 (excluding periods when COVID-19 cases were on the rise).

An annual sports contest (Spartakiad) is held for employees in 18 types of sports. Teams in football, volleyball and other sports represent the Company in various levels of competitions, including Russian national.

Since 2020, the Cherepovets facility provides free psychological support to employees, with in-house psychologists available to them for counselling and advice. As part of the Employee Mental Health Support programme, the Company offers meetings in persons, online interviews, and comprehensive events such as webinars and training sessions to reduce conflicts in teams, improve their psychological resilience, and increase performance levels. Starting from 2022, psychological support is provided by in-house psychologists to employees of Apatit, its branches and subsidiaries.

To promote traditional spiritual values, improve social and psychological climate in the team, and enhance emotional well-being, the Company does a lot to help build and reconstruct Orthodox churches.

Those employees whose children are involved in the DROZD project (Educated and Healthy Children of Russia) annually take part in several joint training sessions and sports contests held among families. At the DROZD sports facilities, our employees can work out and get ready for GTO (Ready for Labour and Defence) fitness tests.

Apatit's target programme for developing gas and mine rescue, fire-fighting and prevention activities for 2019–2022.

In 2022, Apatit's target programme for developing gas and mine rescue, fire-fighting and prevention activities for 2019–2022 was completed at all of Apatit’s branches.

for the programme stood at approximately

- improved training facilities and equipment of gas/mine rescue and fire-fighting units;

- enhanced quality of hands-on training for young hires;

- achieved compliance with gas, mine, fire rescue, and personnel training regulations;

- re-equipped gas/mine rescue and fire-fighting units, new equipment and machinery purchased.

- headcount of the respective business units increased

- purchased:

- equipment – 447 units,

- machinery – 17 units,

- gear – 579 units;

- a new fire brigade station was created at the Kirovsk branch of Apatit;

- two buildings were renovated to accommodate a gas rescue squad.

Transformation of safety culture and OHS management system

Since 2021, we have been running a three-year project called "Transformation of Safety Culture and OHS Management System".

- transforming the safety culture and developing OHS leadership;

- developing, adapting and ensuring the sustainability of best practices in the field of safety culture and OHS management improvements;

- learning how to arrange and carry out works associated with high OHS risks;

- ensuring the sustainability of our performance and the relevance of our management system over the next five years;

- reaching stage 3.1 as per Bradley curve (in 2021, we were at stage 2.2).

The project covers key business units of Apatit, entities under management, subsidiaries and affiliates, and third-party contractors engaged by our production sites.

In 2022, the project delivered its first results, with the level of safety for higher-risk activities improving

and remaining unchanged throughout the year. To maintain and replicate this standard across all its units, the Company established the Transformation Centre, which implements tools to help achieve the project’s goals. These tools include leadership visits, standard operating procedures, audits of hot work, gas hazardous and underground construction work, etc. In 2022, following an audit of the corporate work permit systems in place at the Cherepovets facility and Volkhov branch, PhosAgro resolved that a target model system must be developed, along with an assessment methodology (both are expected to be completed in 2023).