Supply chain

Area, strategic goals and metrics

- Establishing into long-term relationships for the supply of inventory

- long-term agreements

- consignment warehouses

- online shops

- Further development of category strategies

- Lower reject rate

Key projects and highlights of 2022

ESG evaluation of suppliers

- Maintaining an ESG evaluation coverage of

- Audits

- Updating the information provided by counterparties as part of the ESG survey, if more than a year has elapsed since the information was provided

Key projects and highlights of 2022

Training materials are available on the Company’s official website in the Procurement section

Digital transformation

- Process Mining development

- Introducing new robotic solutions

Key projects and highlights of 2022

- Process Mining, an innovative method of data analysis and business process optimisation to manage procurement.

- SCOUT system to verify and monitor the integrity of suppliers.

- Further development and implementation of an automated procurement workstation.

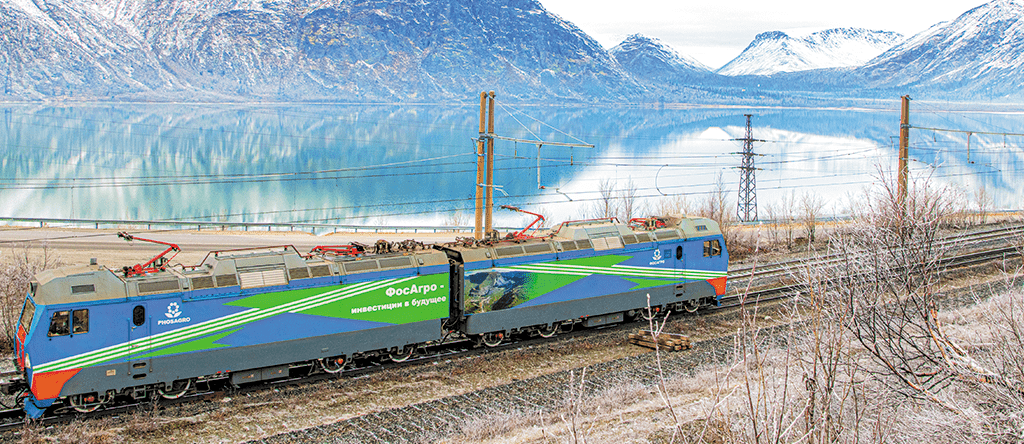

PhosAgro’s procurement system seeks to ensure that the Group’s subsidiaries receive the required resources, materials, and services of adequate quality in full and at reasonable prices. However, there is much more to the principles and business processes underlying our procurement activities. We believe that running a supply chain in an efficient and responsible manner is the cornerstone of the Company’s sustainable development. In 2022, our procurements of goods and services reached almost RUB 214 bln. Thousands of our suppliers and contractors benefit directly from these investments, and so do their employees, who have to provide for their families. We contribute to the public budget at various levels. But what is more important is that the tools that we employ, including our environmental and social assessment of suppliers, as well as anti-corruption mechanisms, directly promote sustainable values across the Russian business community. These values are the bedrock of our business philosophy. We work to ensure that our procurement activities have a strong positive impact on all our stakeholders.

The main objective of procurement is to ensure that the Company's needs for equipment, materials, and services are met in a timely manner, in full and at the best possible prices.

The Group is committed to establishing and maintaining business relationships with companies that operate in line with high ethical standards and combat corruption. Therefore, any supplier that registers on the Company's electronic bidding platform (EBP) must read and understand the above regulations.

Procurement activities

The Company's procurement activities are governed by:

Interaction with suppliers relies on full transparency in decision-making, market and formula pricing, and long-term relationships.

The Company operates a convenient open system for the procurement of goods and services. Procurement procedures are competitive, and information on the needs for materials, equipment or services is published on PhosAgro's EBP. To participate in the bidding, suppliers have to sign up and read the regulations. Evaluation and selection of a supplier are set out in the Company's procedures.

The Company has an anti-fraud and anti-corruption system in place.

PhosAgro seeks to minimise the risks of doing business with suppliers that might be involved in corruption. To this end, the Company has set up a corporate hotline for suppliers and other stakeholders to report on potential irregularities.

- Category management:

the development and implementation of category strategies can significantly reduce costs, increase reliability of supply and improve economic efficiency.

- IT solutions:

- Process Mining, an innovative method of data analysis and business process optimisation to manage procurement;

- SCOUT system to verify and monitor the integrity of suppliers. The system helps to minimise the existing risks and losses by introducing a uniform auditing standard, monitor the condition of suppliers in real time and respond to changes in a timely manner.

- Robotisation of processes

Efficient structure

The past year saw significant changes to the structure of the Procurement Department aimed at both improving its overall efficiency and adapting to new economic realities.

The Procurement Department is responsible for:

- strategic sourcing of raw materials and services;

- operational procurement;

- project-based procurement;

- local procurement;

- alternative procurement (including strategic sourcing of materials and equipment procurement);

- supply chain management;

- planning and analysis.

In order to assess performance, increase employee engagement and motivation, the Department has established KPIs in line with the Company's business objectives to evaluate the extent to which the Department's objectives have been achieved and processes streamlined.

The performance of the Company's procurement function is subject to annual review by PhosAgro's Board of Directors.

Geopolitical factors had a significant impact on PhosAgro Group's supply chains in 2022. The US, EU, Japan, and a number of other countries ceased the supply of equipment. Many contracts had to be renegotiated with amendments to deadlines, prices and payment terms, logistics routes and, in many cases, substitution of goods in signed deals. In addition, banking operations with foreign suppliers became more complicated. To respond to these challenges, PhosAgro introduced structural changes in the Procurement Department, organised alternative procurement with a shift in geographic priorities and new supply chains in place, and took a number of steps to improve the Department's operational efficiency. The timely and successful action enabled us to adapt to the new conditions in a short space of time, restore the continuity of supply to our operations, and maintain an appropriate level of supply stability.

The following strategic risks affect our procurement objectives (for more information, see the Strategic Risks section):

The Group develops corrective measures as necessary and unlocks opportunities to mitigate those risks. Below you can find more information about what we do on this front.

Cost budget in 2022

The Company’s procurement costs in 2022 totalled RUB 213.9 bln, of which raw materials and fuel accounted for 57%.

One of PhosAgro’s top procurement priorities is to cooperate with small- and medium-sized enterprises (SMEs), primarily in the regions where the Company’s key assets are located. In the existing political and economic environment, we view active development of this cooperation benefiting all parties to be even more important.

In 2022, as part of the Synergy of Growth agreement signed in 2020 between the government of the Vologda region, Apatit, Severstal and Urban Development Agency coordinating business development in Cherepovets, we published detailed information on the Company’s need for import-substituting products on Electronic Business Cooperation, an information platform, to identify opportunities for local producers to make and supply these products.

PhosAgro also regularly participates in online and offline meetings held in the regional offices of the Russian Union of Industrialists and Entrepreneurs and the Urban Development Agency in Cherepovets, as well as at exhibitions and strategy sessions.

In 2020, based on the principles of sustainable development set forth in the Code of Conduct for Counterparties, PhosAgro developed a system to evaluate suppliers against ESG criteria relying on the Sustainable Procurement Indicators checklist. The checklist is part of an overall framework for assessing the Company’s and suppliers’ performance to ensure sustainability and reliability in order to benefit our consumers. It includes questions on compliance with the principles of environmental and social responsibility guiding PhosAgro’s operations. The completed checklist confirms that the Company’s supplier shares these principles. An individual supplier rating is based on the checklist.

We believe that making suppliers aware of the Company’s system of values will contribute to a more responsible and sustainable business culture in the long run.

Key ESG evaluation indicators

The indicators for 2022 are based on the total number of suppliers taking part in procurement and the number of rated suppliers. This methodology will apply to future periods as well.

All categories of suppliers were assessed for environmental impact. Suppliers with an environmental management system certified to comply with ISO 14001 or a similar standard accounted for 33% of evaluated producers of raw materials, fuel, energy, and commodities.

Environmental assessment indicators show that 33% of suppliers have an innovative and forward-looking environmental policy and contribute to the protection of the environment.

Technical audits have not identified any counterparties failing to comply with recognised standards with regard to environmental impact.

The results show that more than half of suppliers share PhosAgro’s commitment to equal opportunity policies, do not tolerate harassment or other disrespectful behaviour towards employees and adopted a zero-tolerance stance on child labour.

Some 39% of suppliers in the stated categories exhibit proactive and responsible behaviour towards occupational safety and ensure compliance with international standards set to control working conditions and mitigate occupational and industrial risks.

Technical audits have not identified any counterparties failing to comply with recognised standards with regard to environmental impact